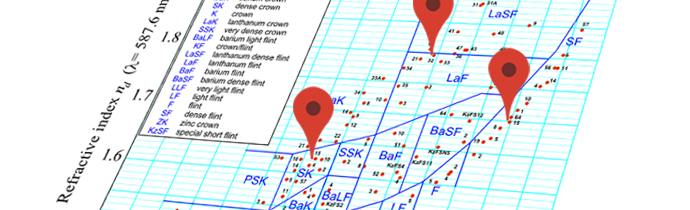

A “glass map” is often the first tool in optical design. The map is a quick way to determine a suitable range of optical materials in terms of refractive index (n) and dispersion (“Abbe number”, “nu number”, or “V-number”). Finding the ideal region on the glass map is only the first step, though. Several “non-optical” factors must be balanced to determine which materials are most promising. We’ll consider 5 of the most important.

- Cost: Money, money, money is a principal factor in any engineering problem. With that said, cost is never the only factor. The goal of optimizing a design is to find the least expensive solution that still meets the performance specification.

- Availability: Just because an optical material used to be easy to find doesn’t mean that it is now. Some glasses are discontinued. For example, many glass materials contained lead, such as the very popular glass BK7. N-BK7 is a lead-free glass similar to BK7; the two glasses are similar but not equivalent. The point is, make sure that you have up-to-date information on material availability before you start your optical design.

- Workability: Optical materials are notoriously sensitive to heat, pressure, and abrasion. Unfortunately, optical manufacturing involves high-stress processes such as grinding, polishing, molding, and thermal curing. Make sure that the materials you consider are compatible with the manufacturing processes at your disposal.

- Environment: An optical system’s final application needs to be considered when designing the optical elements. Glasses, polymers, and crystals all have thermal expansion, solubility, corrosion, and surface-toughness limits. Limit your material choices to those that can withstand their work environment.

- System effects: Remember that an optical system is an “ecosystem” of inter-operating parts. Solving a problem in one area can create another problem elsewhere. For example, some coatings are difficult to grow on certain materials; therefore, turning a “lens” problem into a “coating” problem does not actually solve the optics problem. Be sure to consider how different decisions and processes will affect each other when optimizing your optical design.

As you can see, finding the best optical material isn’t as simple as choosing a spot on a map. As with any voyage, you have to figure out if the place really exists, if there is a trail, if the environment is hospitable, whether you can afford it, and whether your team will work together to get there. The advantage of all that foresight is that you eliminate a lot of dead ends, which means you will get to the best solution faster.

Need help choosing a material? Ross Optical’s experienced engineering team will consider cost and performance tradeoffs, examine the available options, and recommend the optical material that best fits your application.

Contact Lisa Yang, Chief Technical Officer, to discuss your needs.

Lisa@rossoptical.com

915-595-5417 x18

Our free guide includes cost considerations for optical systems, mechanical and coating design, and designing with specialty optics. Download it now!