Whether measuring human temperatures with no-contact thermometers, studying the thermal properties of a distant planet, or enabling military-grade motion detection, infrared (IR) optics are in demand. The IR band of the spectrum -- from 750 nanometers (nm) in the near-IR to 12 microns (µm) in the long wave or LWIR -- while not visible to the human eye, is easily detectable with specialized imaging systems. These systems rely on well-crafted optics to help users gather and process thermal signatures and help users detect and see those signatures with high-level contrast and clarity. To achieve optimal outcomes with imagers and detectors in these wavelengths, customized lenses, materials, and coatings are fundamental.

Invisible rays

British astronomer William Herschel is credited with discovering infrared radiation and was the first to deduce and write about the “invisible rays” beyond visible red. In 1800, when experimenting with a prism and thermometers, he measured a temperature difference later categorized as infrared radiation.

Initially, IR technology was available only for military applications due to the expense of working in that range and because of IRs ultra-sensitive detection capabilities. In 1992, however, just before a Honeywell patent for a breakthrough uncooled microbolometer, the U.S. declassified the technology. The introduction of this type of uncooled microbolometer, unlike those requiring cryogenic temperatures, was a turning point and enabled affordable IR imaging to reach new markets.

As the costs of thermography dropped, commercial applications skyrocketed. Consider this partial list: law enforcement, commercial and industrial laser applications, monitoring, security, transportation, firefighting, medical fluorescence detection and imaging, industrial vision systems, medical and analytical instruments, telecom, consumer products, astronomy, and more.

Atmospheric Transmission Windows

The IR wavelength is divided into four ranges: near infrared (NIR): ~750nm – 1.0µ; short wave infrared (SWIR): ~1.0µm to 3.0µm; midwave infrared (MWIR): ~3.0µm - 5.0µm; and long wavelength infrared (LWIR): ~8.0µm - 12.0µm. Different types of optics, sensors, light source technologies, and applications align with these various atmospheric transmission “windows.”

In the NIR, objects not visible to the human eye still reflect some light. Popular devices that “see” this very dim reflected light include night vision cameras, medical lasers, fluorescence detectors, even garage door “electric eye” sensors. The optical systems in these devices comprise an inexpensive light source and sensor, combined with a lens manufactured from common glass or plastic.

SWIR wavelengths scatter less and travel better through the atmosphere than NIR, which means they can penetrate smoke and fog and are therefore well suited for telecom, both freespace, and fiber optic. SWIR is also useful to military imaging and various industrial machine vision applications. Its systems tend to be more expensive because materials and manufacturing processes are more complex; lenses are made of specialized crystalline materials such as fused silica or calcium fluoride (Ca F2), and the imaging sensors, which are extremely sensitive, traditionally have a photodetector that needs to be indium bump bonded to a silicon readout circuit. Results, however, often justify the expense.

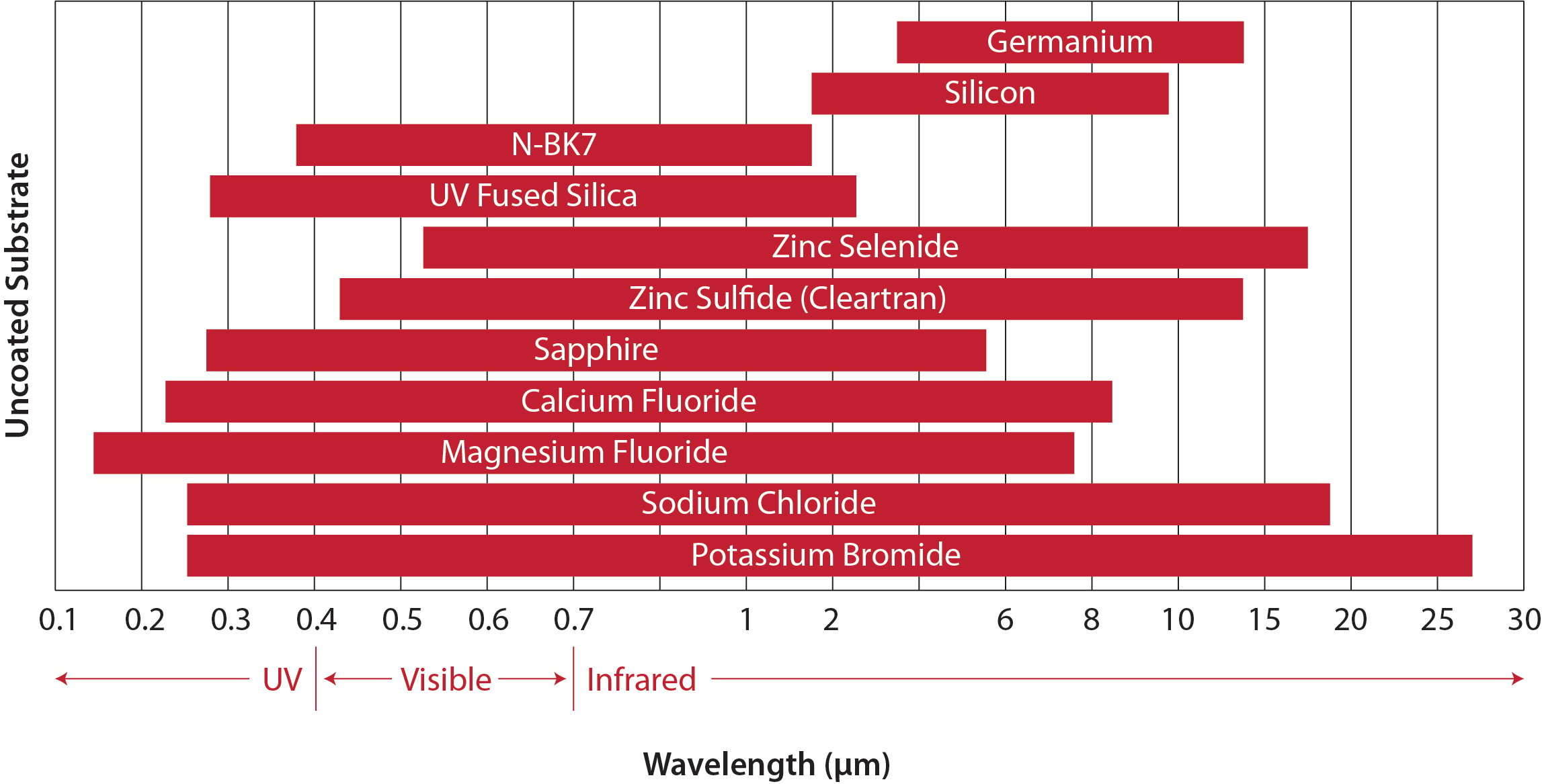

In the MWIR, objects can be seen by their self-generated “blackbody” (Plank) radiation. This means that the optical system helps distinguish and visually contrast emitted and ambient temperatures. Popular for detailed military imaging in surveillance and reconnaissance, astronomy, and sophisticated medical equipment, imagers designed and calibrated for this spectral region can also be useful -- with the addition of a cooled band gate filter -- for detecting odorless hydrocarbon gasses such as butane and propane. MWIR imagers have become an invaluable tool for leak detection. It’s common for MWIR systems to rely on cooled sensors and very precise crystalline substrate materials, with optics made from materials such as germanium (Ge), silicon (Si), zinc sulfide (ZnS), zinc selenide (ZnSe), magnesium fluoride (MgF2), and sapphire. If the optics need to be ruggedized or able to withstand high laser damage thresholds, specialized thin film coatings may also be necessary. Because of the varying chemical composition of each substrate, coatings are applied with reactive processes such as chemical vapor deposition (CVD), with additional bonding layers, as necessary.

Figure 4: Infrared Substrate Comparison

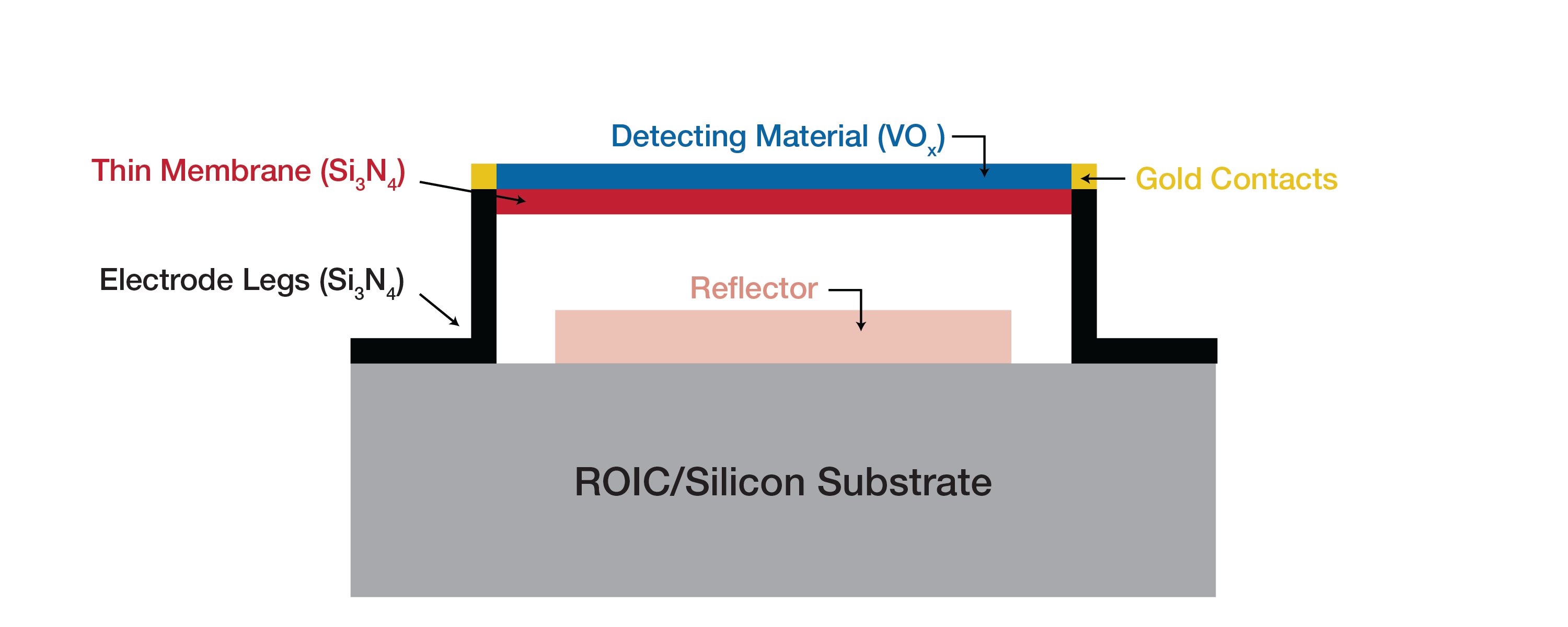

For LWIR, systems can be adapted to ultra-precise military surveillance over distances or less sensitive civilian law enforcement. In recent years, LWIR has expanded beyond industrial applications into medical imaging, particularly during the coronavirus pandemic for contactless human fever screenings. The lenses for LWIR systems are mass-produced precision optical components and readily available. The use of various chalcogenides, which are a type of semiconductor material, is on the rise because they offer a potentially low-cost, moldable, effective, and readily available lens solution. Central to the LWIR imaging system is an uncooled microbolometer, which is fabricated right on a silicon chip. The microbolometer is responsible for reading and registering detected temperature differences.

Figure 5. Microbolometer layer

Ross Expertise

Ross Optics has been manufacturing lenses for over 30 years and we understand that selecting the right optics for complex projects requires collaboration with a trusted team of experts. Give us a call and let us help you discern the best optics for your system’s requirements, and the best materials to meet your time and fiscal budgets.

Optics are an integral component of today’s light-based technologies — laser systems with applications in medicine and defense, fiber optic, satellite communication, machine vision, thermal sensing, imaging, autonomous vehicles, and more. Yet, optics remain shrouded in mystery.

So to make the design process more transparent and enjoyable, we put together this introduction to optics. We’ve answered many of our customers’ most common questions with easy-to-understand definitions and basic illustrations.