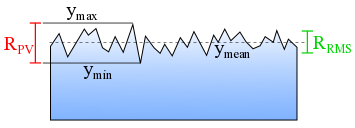

Surface roughness is a measure of high-frequency deviations in the departure of a surface from ideal. Surface roughness can result in unwanted scattering in an optical system and for many optical applications one might think it is always best to minimize surface roughness. However, simply minimizing surface roughness without regard to system wavelength and performance can result in increased costs and longer production times. When choosing specifications for a particular optical component, it is important to consider the function of the component in the context of the entire optical system in which it will be used. A careful analysis of the role surface roughness plays in a system can avoid unnecessary production costs due to over-specification. For example, a 10 Angstrom RMS surface roughness can impact a system operating in the visible region more significantly than a system operating in the mid or far infrared.

Read More >Chris Toomey and the Ross Team

Recent Posts

Surface Roughness Specifications

By

Chris Toomey and the Ross Team | Jun 5, 2020 10:00:00 AM

COMMENTS

SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (12)

- custom optics (11)

- optical assemblies (11)

- micro optics (10)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)