Because cylindrical and spherical optics both have circular profiles when viewed end-on, it is a common misconception that identical production methods apply to both. Both methods do use similar principles of grinding and polishing, but there are a number of very important differences. Here are three of the most significant areas of difference.

Read More >Damon Diehl

Recent Posts

Differences and Similarities between Cylinder and Spherical Lens Fabrication

5 Tips for Cleaning Your Optics with a Clear Conscience

Dirty optics are trouble. They diminish performance, and in high-energy systems, they can even cause physical damage. Plus, well...they just plain look bad. When faced with an unsightly smudge or bit of dirt, it’s tempting to buff it off with the nearest piece of Kleenex. More likely than not, if you do that, you’re going to end up with a dirty, damaged optic. So, put down that handkerchief. Here are five things you need to know before you touch any optical surface.

Read More >More Than Meets the Eye: Surface Specification & Optical Performance

For better or worse, we do “judge a book by its cover.” Appearance can override our better judgment. It’s tempting to judge the quality of an optical element based on its appearance, but that overlooks the element’s role within the overall optical system. In this article we’ll consider three types of surface irregularities and explore how each type can affect optical performance.

Read More >Designing for Reality: Four Ways to Ensure Functional Optical Components & Systems

There is more to optical design than designing the optics. A design that works on a computer screen may not work in real life. Here are four best practices to help you design for manufacturability and performance.

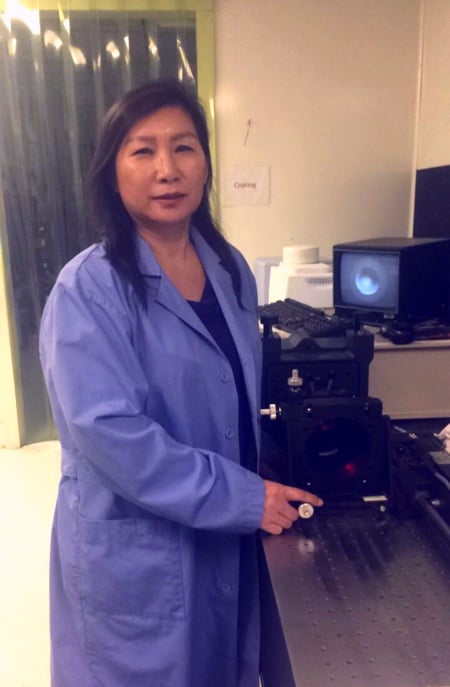

Read More >Women in Optics: How Lisa Yang Went from Curious Science Student to Optical Design Expert

We asked Lisa Yang, Chief Technology Officer at Ross Optical, to share a bit about how she got into the field of optics and the work she does now.

Read More >The Hunt for Large Lenses Stops Here

Do other optics suppliers think you’re weird for wanting large lenses? We don’t.

As more and more optical suppliers consolidate and streamline their businesses, few continue to carry large diameter lenses. This is problematic because large diameter optics remain critical for precision instruments such as telescopes and imagers.

Read More >Three Times You Might Need to Reverse Engineer an Optical Component

3 Reasons to Reverse Engineer

“Reverse engineering” is a term with a bad reputation. It calls to mind patent violations and expensive legal wranglings. There are legitimate situations, though, when a company might need to work backwards to design an optical component that matches the performance of a commercial item.

Read More >Keeping an Eye on Upcoming ITAR Changes

As a registered ITAR supplier, Ross Optical and is carefully tracking ITAR changes and what they could mean to you and your optics supply chain.*

Read More >Avoiding Cost Traps in Optical Design

In previous posts we have offered advice on designing optical systems for ease of assembly, performance, and manufacturability. Incorporating cost considerations into optical design is another important part of the process. The topic of cost optimization could fill an entire course (like Rich Youngworth’s), but for starters, here are four critical design traps that will always increase your system cost.

Read More >Choosing a Custom Optics Solution: 3 Tips for OEMs

Newton's Cradle: The end-user market impacts OEMs and vendors further up the supply chain.

Supply Chain Challenges

Being an original equipment manufacturer is a weighty responsibility. As an OEM you provide critical components for your customers’ products, and you never want to be the bottleneck that holds up production.

OEMs of optical products face special challenges. Optical elements require precision fabrication, which can entail a long lead time. Those lead times are compounded when a component requires custom optics. In such a situation it can become difficult to supply a customer’s needs consistently without ending up with an expensive inventory of unsold components.

Read More >SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (13)

- custom optics (11)

- micro optics (11)

- optical assemblies (11)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)