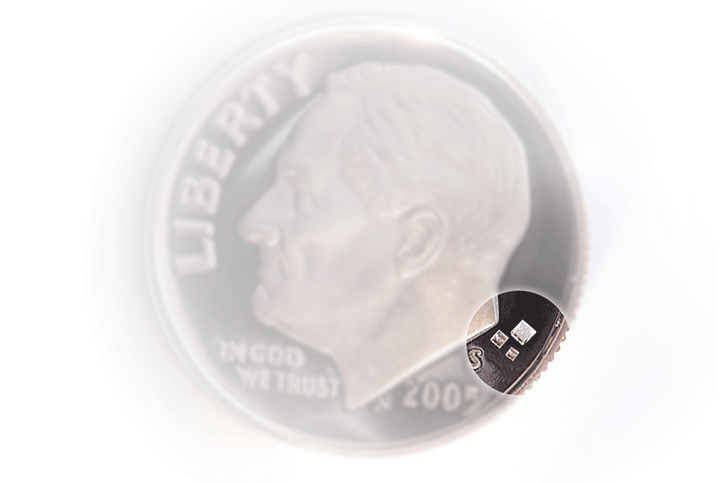

Keep in mind that a human hair is about 100 um (0.100 mm) diameter! When most people think about specifying micro-optics (< 1 mm in size), they assume they are just very small versions of standard optical components and all the manufacturing methods and specifications are the same. This is not the case! Modern manufacturing techniques for larger optics have evolved to the point where you typically do not have to think much about them when designing an optical system and many of the potential manufacturing issues are no longer considered. In the realm of micro-optics, many of the old limitations and considerations still apply.

Read More >Chris Toomey

Recent Posts

So You Think You Know Micro-Optics…

COVID-19 Update: Ross Optical is an Essential Business

Many state and local authorities are beginning to set guidelines for the operation of businesses to mitigate the spread of the COVID-19 virus. Ross Optical would like to keep you informed on the situation at our location in El Paso, TX.

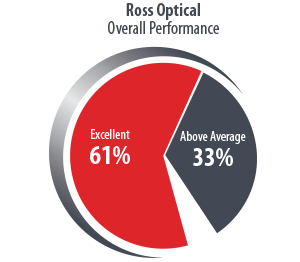

Read More >2019 Survey: Ross Optical Meets Customer Service, Quality, and Delivery Needs

With the completion of our 2019 customer service survey, Ross Optical is pleased to once again receive high marks for customer service, technical expertise, quality and delivery. This year, 94% of customers rated Ross above average or excellent!

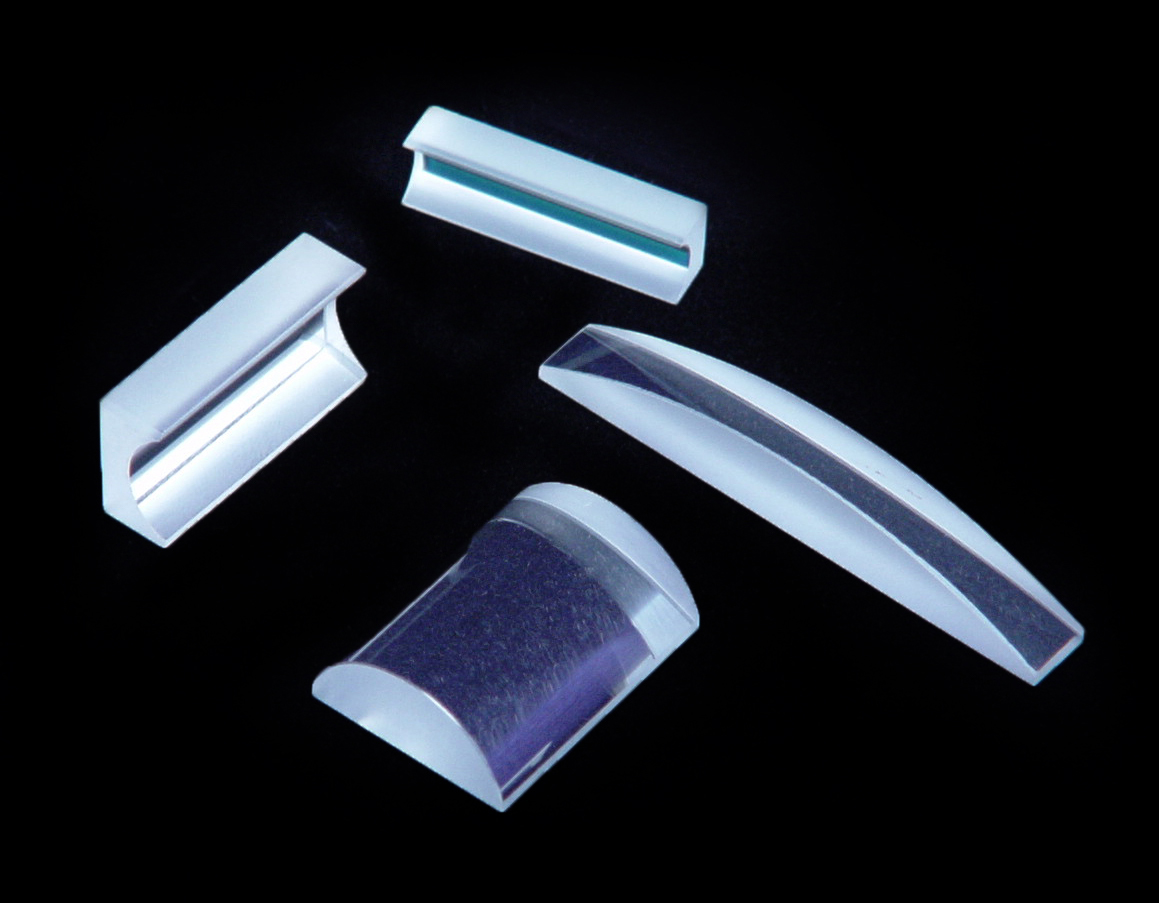

When to Utilize Stock Versus Custom Optics

There are many factors to consider when manufacturing optical lenses. From optical system design to production, determining when to use a stock lens versus customizing a specific lens plays a major role in this decision. While most applications can be serviced with stock lenses, leveraging custom options can be beneficial depending on the application. Working with an optical manufacturer like Ross to utilize their expertise can be very valuable when making your decision.

Read More >Tips and Techniques for Cleaning Optics

Ideally, your optics are kept pristine and no cleaning is necessary-- but the reality is that almost all optics will require cleaning at some point. Optics are like pets, when it comes to maintenance: each one has its own unique characteristics and issues. The first step is to ensure you have a clean, contaminant free work surface such as a tray or hard surface table. Next, use only clean, powder-free gloves or finger cots. Always handle optics by the edges to avoid contaminating or damaging the lens surface.

Read More >SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (13)

- custom optics (11)

- micro optics (11)

- optical assemblies (11)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)