This article is the last of our three-part series on optical design secrets. In previous

Secrets of Optical Design, Part 3: Mastering Design Software

Ross is Collecting Healthy Food for Food Drive

We are helping to collect healthy food for the Mujer Saludable, Familia Feliz. Want to help out by donating? There are two ways to help:

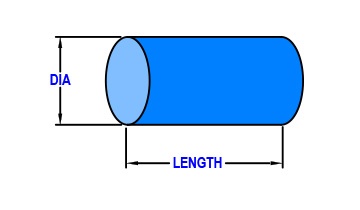

Read More >Three Applications of Rod Lenses

A previous article explored applications of cylinder lenses. In those examples, the lenses were only curved on one side—the other side was flat (i.e. "plano-"). Cylinder lenses can be curved on both sides, though, creating a "rod lens." Rod lenses are unique in that they can be used either side-on or end-on depending upon the application. Here are three examples of their versatility.

Read More >Secrets of Optical Design, Part 2: Sourcing Optics

This article is the second in our three-part series on "secrets" that good optical designers must understand in order to become great. These tips are things that you can only learn from experience---or reading these articles!

In this article, we identify some of the supply-side challenges that optical designers face and offer some solutions. This knowledge will help you develop and protect your supply chain.

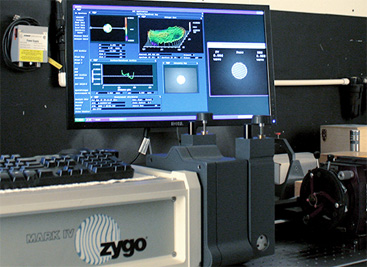

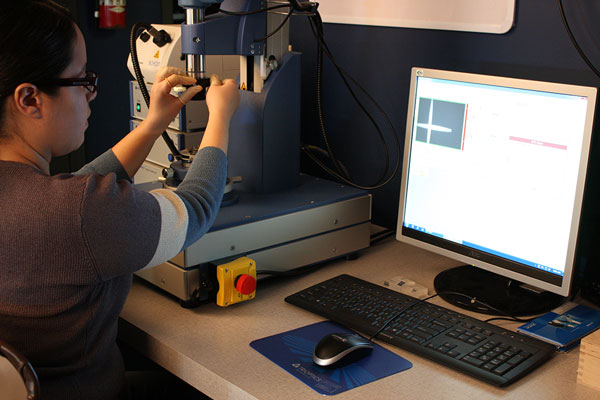

Read More >Ross Optics Improves Micro Optics Capabilities

Secrets of Optical Design, Part 1: Understanding Optical Manufacturing

This article is the first of a three-part series on aspects of design that are sometimes overlooked in optics courses. Optical design is often as much art as science. However, it is not magic! Like any art or science, skill in the trade comes only with experience and practice. That said, you can save time by learning from the experience of others.

Read More >The Importance of Designing for Optical Assembly

The optical assembly process is often treated as an afterthought of the design process; however, once a product has gone into production, assembly becomes a dominant cost. Designing for ease of assembly becomes a considerable cost-saver in the long run. Below we offer three important points to consider as you develop a product.

Read More >Top 3 Reasons for Long Lead Times in Optical Manufacturing: Part 1 in our Reducing Lead Time Series

Our series explains how Ross Optical can help you reduce lead time on your orders. This article will explain the three factors that most impact lead time for optical components:

- Choice of materials

- Method of fabrication

- Method of testing

While these three factors impact any manufacturing process, they present unique challenges in optical manufacturing.

Read More >Optical Design: Five Tolerancing Guidelines for Smart Designers

In the design of any optical system, managing cost versus performance is always a challenge. When faced with this challenge, it is important to realize that properly tolerancing the design is every bit as important as the design itself.

Read More >Security Blanket: How Blanket Purchase Orders Can Protect Your Optics Supply Chain

For companies struggling with supply chain dilemmas, one of the solutions we offer is blanket purchase orders to help ensure a reliable stream of components. To understand whether a blanket purchase order is right for you, you need to understand how they work.

Read More >SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (12)

- custom optics (11)

- optical assemblies (11)

- micro optics (10)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)