Demand for infrared optical elements has extended beyond just lens assemblies and hot/cold mirrors. Specifically, there is growing interest across the optical industry for bandpass filters, achromats, athermal elements, and polarizing waveplates. The demand spans all IR wavelength bands—near IR (0.75 µm to 1.4 µm), short-wavelength IR (1.4 µm to 3 µm), mid-wavelength IR (3 µm to 8 µm), and long-wavelength IR (8 µm to 15 µm). Advances in sensor and source technology, as well as a changing marketplace, are driving this growth. Demand from three industries stands out as particularly noteworthy:

Read More >Warming Up: Three Hot Markets for the Infrared Optical Industry

Ross Optical Quality Management System Achieves ISO 9001:2015 Certification

This international certification will save customers time during the qualification stage of the procurement process.

Read More >Moving Forward in Reverse: Six Steps for Reverse-Engineering Out of a Supply-Chain Collapse

The Situation

Read More >Meet the Team: Charlie Metzger, Technical Sales Engineer

Charlie has been in the optics business for over 40 years and with Ross for 8. With a background in industrial engineering, Charlie enjoys interacting with engineers in their element—getting out on the shop floor and talking technical details in order to help customers manufacture better products.

Read More >FAQ: Tolerances & Tips for Super-Polished Optics

What is super-polishing?

Super-polishing is a new classification for optical surface quality, sometimes referred to as "atomically smooth." By this we mean surface roughness features that can be measured in Angstroms, which are ten times smaller than nanometers. A single hydrogen atom is roughly 1 Å in diameter, so super-polishing really is “atomic.” By comparison, a λ/100 specification is 6 nm.

Read More >Cleaning Optical Mirrors vs. Lenses: 3 Key Differences

The recommended procedures for cleaning optics are largely the same whether you are working with lenses or mirrors. The typical cleaning process involves first blowing dust and dirt off the optical component with pressurized air, then using the drag method to slowly move moistened lens paper across the optical surface. We’ve previously shared tips for avoiding damage during optical cleaning. However, a few key differences make mirrors more susceptible to accidental damage.

Read More >Providing Optical Design Support During the Contract Development Process

At Ross Optical, we take pride in our reputation for outstanding customer support. A big reason for our customers' satisfaction is how we handle customers before they are our customers. Many optical suppliers require contracts and commitments before they will help a customer with design issues. At Ross, we think that's backward. Getting to the best design can take some time, and we prefer to help our customers overcome those design hurdles before committing to an order. The design collaboration process varies from customer to customer, but it typically goes something like this:

Read More >Rethinking What’s Possible in Optical Coating

Penn Optical Coatings is a partner of Ross Optical. Ross does a number of coatings in-house, but when our customers have more complex or custom project, we know we can rely on Penn’s expertise and attention to quality.

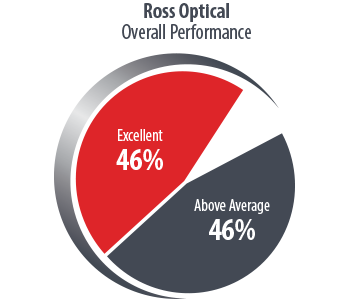

Read More >2017 Survey: Ross Optical Continues to Meet Customer Service, Quality and Delivery Needs

Meeting Needs, By the Numbers

We just completed our 2017 customer survey, and Ross Optical once again received high marks for customer service, technical expertise, quality and delivery. On overall performance, 92% of customers rated Ross above average or excellent.

Read More >Outsourcing Optical Assembly: 4 Cost Considerations

Optical assembly is an important step in the production of an optical system—as well as a major cost driver. As we’ve previously discussed, designing optics with assembly in mind can ease the transition from prototype to final product and save money in the long run. But beyond design, the “who” and “where” of assembly can also affect price.

SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (12)

- custom optics (11)

- optical assemblies (11)

- micro optics (10)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)