Erika joined Ross Optical in 2010. Starting in the Quality Department and then

transitioning into the role of Operations Manager showcases her adaptability and

expertise in ensuring quality and efficiency throughout the production process. Her roles

undoubtedly contribute to the company's success and reputation for excellence in the

industry.

Meet the team: Erika Salayandia

Meet the team: Carlos Penalbert

Carlos Penalbert recently joined the Ross Team. With 20 years of optics and thin-film coating expertise, Carlos brings a wealth of experience specializing in thin film engineering, sales, and a passion for customer satisfaction.

Read More >Meet the team: Adriana Garcia

Adriana Garcia joined Ross Optical in 2018. Initially joining the team to help in customer service and sales she has moved into the role of New Business and Digital Marketing Manager. We sat down with her and found out more about her background, her work at Ross, and what her favorite hobby is.

Read More >Ross Optical Excels in 2023 Customer Service Survey Results

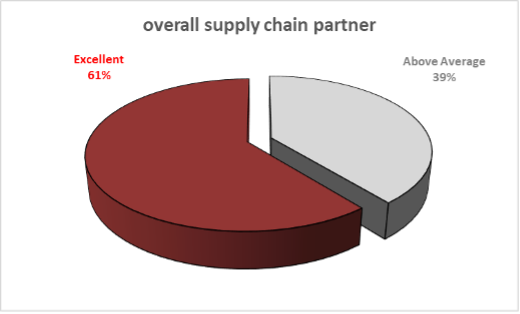

We are delighted to announce the successful conclusion of our 2023 customer service survey at Ross Optical, wherein we have once again received commendable ratings for various key metrics, including customer service, technical expertise, quality, and delivery.

Read More >Ross Optical Summer 2023 Hours

Summer 2023 HoursIn order to give our employees well-deserved time with their families this summer, our summer hours begin on Monday, June 5th, 2023. Regular business hours will resume on Tuesday, September 5th, 2023. Here's the schedule: Summer Hours: Begin: Monday, June 5th End: Thursday, August 31st Hours: Monday-Thursday, 6:00 am - 4:30 pm MDT Fridays: CLOSED No Friday shipments except in extreme emergencies. Holidays & InventoryIn addition, to continue to improve our services, we will have two weeks where there will be no shipments. So plan on placing upcoming orders by June 26th to ensure fast delivery! Closed for our annual holiday: Monday, July 3rd - Friday, July 7th Closed for physical inventory: Monday, July 10th through Thursday, July 13th (No shipments during this week, however our sales team is available during this week to assist you as needed) |

The Pros of Large Diameter Optics in Space

The Pros of Large Diameter Optics in Space

To achieve higher resolution and sensitivity in extraterrestrial observations, larger diameter optics are being developed and used in space applications. Telescopes and observation instruments with up to 12 inches (30cm) diameter optics have proven to be beneficial in enabling more accurate data collection and analysis.

Read More >2022 Survey: Ross Optical Meets Customer Service, Quality, and Delivery Needs

With the completion of our 2022 customer service survey, Ross Optical is pleased to once again receive high marks for customer service, technical expertise, quality, and delivery. This year, 100% of customers rated Ross above average or excellent as an overall supply chain partner!

Read More >Summer Hours

In order to give our employees well-deserved time with their families this summer, our summer hours begin on Tuesday, May 31, 2022. Regular business hours will resume on Tuesday, September 6.

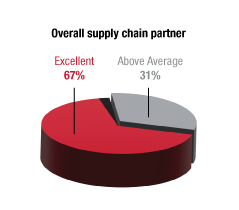

Read More >2021 Survey: Ross Optical Meets Customer Service, Quality, and Delivery Needs

With the completion of our 2021 customer service survey, Ross Optical is pleased to once again receive high marks for customer service, technical expertise, quality, and delivery. This year, 98% of customers rated Ross above average or excellent as an overall supply chain partner!

Read More >Precision Optics Merges with Lighthouse Imaging

Forms a Powerhouse in Optical Design and Volume Manufacture for Medical Device Imaging Systems and Safer, Single-Use Devices

Precision Optics Corporation, Inc. (OTCQB: PEYE), a leading designer and manufacturer of advanced optical instruments, announces a strategic merger with Lighthouse Imaging LLC (“Lighthouse Imaging”). The merger combines two leaders in medical optics and digital imaging, helping customers leverage Precision Optics’ next-generation micro-optics capabilities with Lighthouse Imaging’s leading-edge optical imaging electronics and systems integration. Together, the two companies take precision optical imaging solutions from concept into commercialization at scale, helping product development teams partner with a single source for optical modules, endoscopic equipment, and complex illumination systems.

SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (12)

- meet the team (11)

- optical assemblies (11)

- micro optics (10)

- quality management (10)

- custom optics (9)

- news (9)

- medical optics (5)

- optical coating (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)