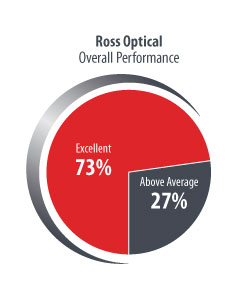

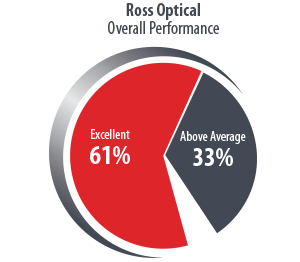

With the completion of our 2020 customer service survey, Ross Optical is pleased to once again receive high marks for customer service, technical expertise, quality, and delivery. This year, 100% of customers rated Ross above average or excellent!

2020 Survey: Ross Optical Meets Customer Service, Quality, and Delivery Needs

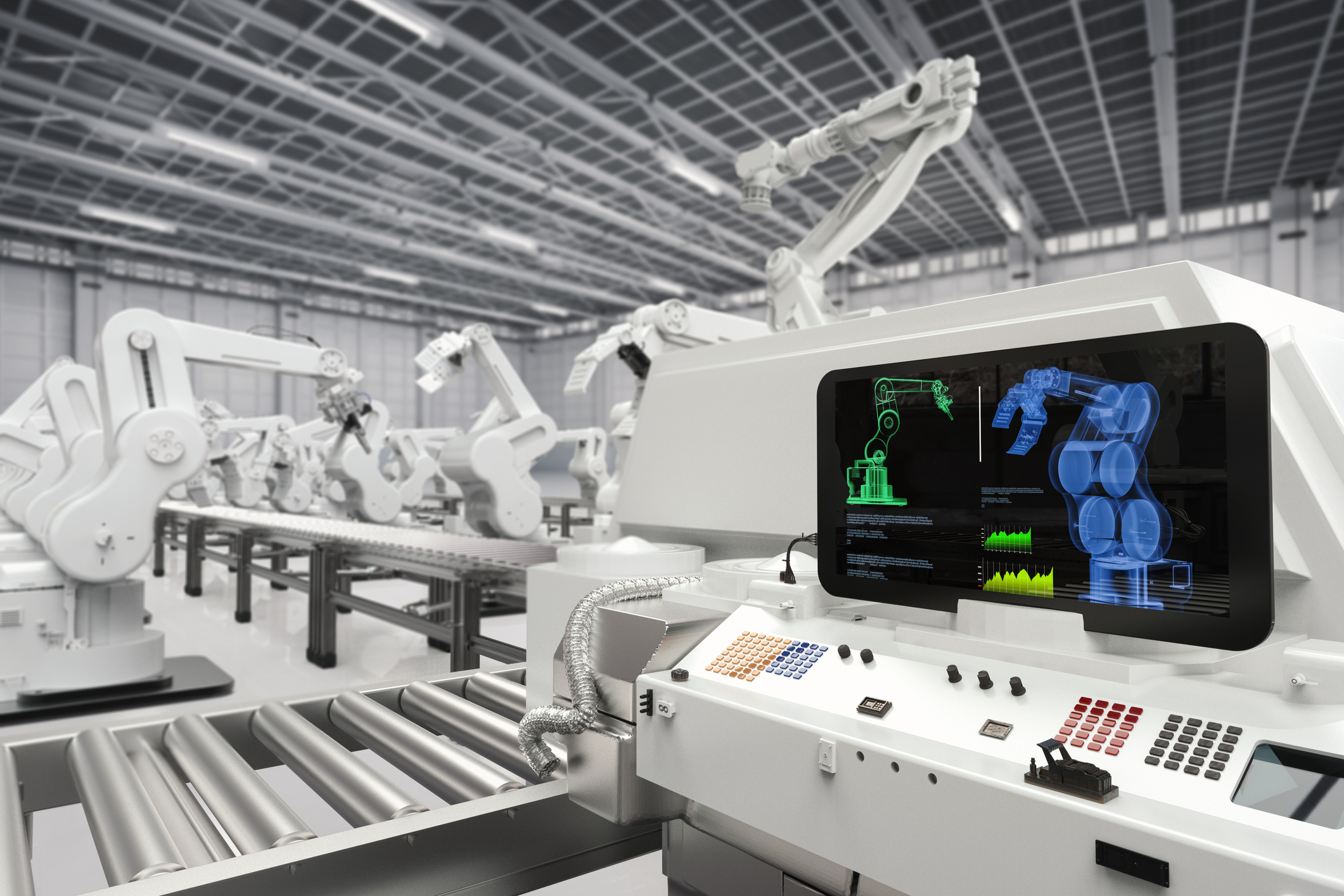

Optical Components for Machine Vision

Machine vision is a technology that enables automated devices to "see." Machine vision systems combine optics and mechanics to create tools that can adjust optics in real-time to perform inspections and aid robotic systems. In our increasingly automated world, machine vision has become an essential component in manufacturing, farming, robotics, and many other areas. Quality optical components are critical to the function of machine vision systems. Optical systems for machine vision may involve high quality fixed focal length lenses, telecentric, or adjustable lens systems (zoom or liquid lenses).

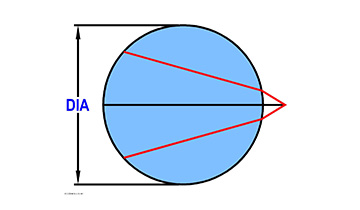

Read More >Working with Ball Lenses

Ball lenses are highly transparent spheres made with optical glass. Some of the earliest microscope lenses — developed by Antoni van Leeuwenhoek — relied on surface tension to form small spheres from melted glass. These lenses achieved magnifications as large as 275x and were as small as 1.5 mm in diameter.1 However, since ball lenses can cause spherical aberrations and typically have to be apertured to exclude non-paraxial rays when used for imaging, they are often replaced with different geometries, such as aspheric lenses, in microscopes today. Modern technologies involve using ball lenses to couple light between optical fibers or to focus light from a diode laser into a fiber optic. Ball lenses are commonly used in barcode scanning, optical sensing, and endoscopy.

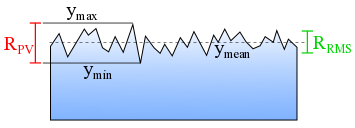

Read More >Surface Roughness Specifications

Surface roughness is a measure of high-frequency deviations in the departure of a surface from ideal. Surface roughness can result in unwanted scattering in an optical system and for many optical applications one might think it is always best to minimize surface roughness. However, simply minimizing surface roughness without regard to system wavelength and performance can result in increased costs and longer production times. When choosing specifications for a particular optical component, it is important to consider the function of the component in the context of the entire optical system in which it will be used. A careful analysis of the role surface roughness plays in a system can avoid unnecessary production costs due to over-specification. For example, a 10 Angstrom RMS surface roughness can impact a system operating in the visible region more significantly than a system operating in the mid or far infrared.

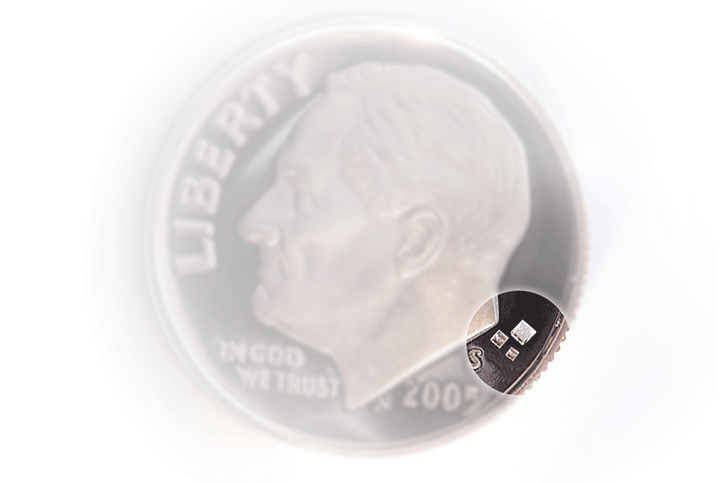

Read More >So You Think You Know Micro-Optics…

Keep in mind that a human hair is about 100 um (0.100 mm) diameter! When most people think about specifying micro-optics (< 1 mm in size), they assume they are just very small versions of standard optical components and all the manufacturing methods and specifications are the same. This is not the case! Modern manufacturing techniques for larger optics have evolved to the point where you typically do not have to think much about them when designing an optical system and many of the potential manufacturing issues are no longer considered. In the realm of micro-optics, many of the old limitations and considerations still apply.

Read More >COVID-19 Update: Ross Optical is an Essential Business

Many state and local authorities are beginning to set guidelines for the operation of businesses to mitigate the spread of the COVID-19 virus. Ross Optical would like to keep you informed on the situation at our location in El Paso, TX.

Read More >The Truth About Scratch and Dig

The following is shared Shared with permission of David Aikens, Savvy Optics:

Read More >2019 Survey: Ross Optical Meets Customer Service, Quality, and Delivery Needs

With the completion of our 2019 customer service survey, Ross Optical is pleased to once again receive high marks for customer service, technical expertise, quality and delivery. This year, 94% of customers rated Ross above average or excellent!

When to Utilize Stock Versus Custom Optics

There are many factors to consider when manufacturing optical lenses. From optical system design to production, determining when to use a stock lens versus customizing a specific lens plays a major role in this decision. While most applications can be serviced with stock lenses, leveraging custom options can be beneficial depending on the application. Working with an optical manufacturer like Ross to utilize their expertise can be very valuable when making your decision.

Read More >Hard Lessons in Optical Design

In the fast-moving industry of optics, there are often problems that arise and need to be dealt with immediately in order to keep production running smoothly and on schedule. Whether they occur in the design, manufacturing, or assembly stage, problems can prove to be catastrophic if not handled properly. Below, we touch upon a few real issues in all three of these stages of optics and give some advice on how to keep your operation running efficiently.

Read More >SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (12)

- custom optics (11)

- optical assemblies (11)

- micro optics (10)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)

.jpg)