The International Traffic in Arms Regulations (ITAR) exist to control access to sensitive, defense-related technology. It is obvious that companies working directly in the defense industry must understand ITAR, but it is equally important for companies that supply or subcontract sub-components, software, or services to defense-related products. Keeping up with ITAR is challenging for small companies with limited resources, because the regulations are dynamic and can change over time.

Read More >Ross Team

Recent Posts

Two New Resources for Maintaining ITAR Compliance

Ross Optical at Laser World of Photonics Munich

Ross Optical Announces Soliton Laser und Messtechnik GmbH as New Distributor Partner

El Paso, TX (April 8, 2019) Ross Optical announced today that Soliton Laser und Messtechnik GmbH will be their official representative in Germany and surrounding countries. Soliton was founded in 1990 and has established itself as a premier provider of optical solutions. Soliton maintains a corporate philosophy of selling with a high level of technical knowledge, as well as fast and reliable customer support.

Read More >Trends in Precision Optical Manufacturing

APOMA, the American Precision Optics Manufacturing Association, is a working group of top optical manufacturers throughout the United States. The organization shares and establishes best practices for optical fabrication and testing. It also provides a unified voice for promoting and advancing the optics industry on a national and international level. Optics is a constantly changing industry. Here are three new business challenges that stood out to us during a recent APOMA meeting.

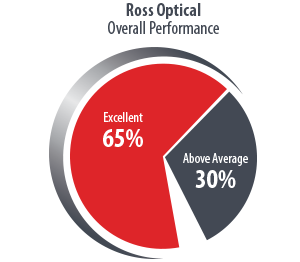

Read More >2018 Survey: Ross Optical Continues to Meet Customer Service, Quality and Delivery Needs

We just completed our 2018 customer survey, and Ross Optical once again received high marks for customer service, technical expertise, quality and delivery. On overall performance, 95% of customers rated Ross above-average or excellent.

Ross Optical Announces Successful ISO 9001:2015 Surveillance Audit

Ross Optical today announced that it has successfully passed the surveillance audit against the ISO 9001:2015 Standard with no non-conformances. The audit was completed by Perry Johnson Registrars, Inc. This certification affords the company’s U.S. and international customers a globally recognized standard of quality assurance. Ross Optical achieved ISO 9001:2015 certification in January of 2018.

Read More >Ross Celebrates 30th Anniversary

Ross Optical is celebrating its 30thanniversary this year. We sat down with Ed Ross, founder, and Divi Mangadu, president, to talk about the last 30 years and what is next for the company.

Read More >Big Trends for Tiny Optics in Medical Devices

Medical technologies are becoming increasingly miniaturized and mobile. This trend is changing the landscape of healthcare and making advances in telemedicine, wearables, and mHealth (mobile health) possible. These technologies include:

Read More >Supply Chain Optimization in Optics: Types of Inventory and Vendor Management

According to KPMG, only 1 in 5 companies say that their supply chain is deployed and optimized to keep pace with customer needs. Supply chain optimization can seem like a daunting task, especially with the long lead times in the optical lens and assembly industry. But it can have a huge reward in cost savings.

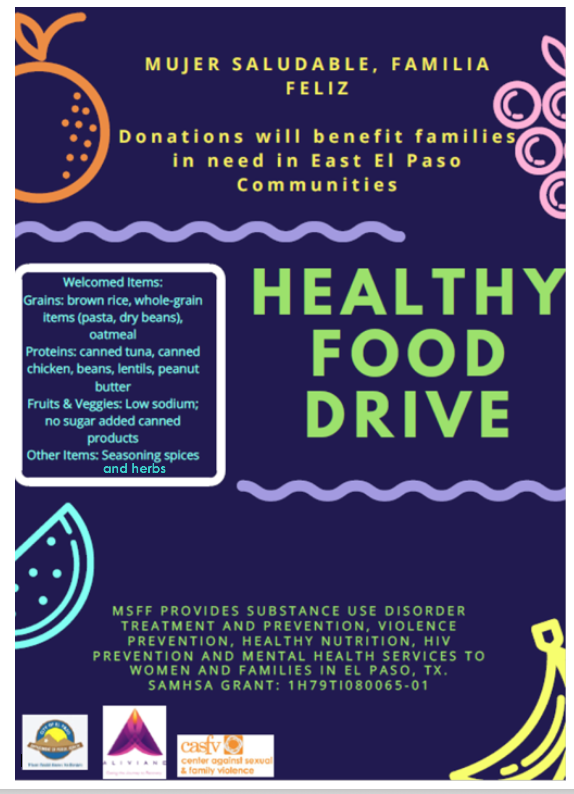

Read More >Ross is Collecting Healthy Food for Food Drive

We are helping to collect healthy food for the Mujer Saludable, Familia Feliz. Want to help out by donating? There are two ways to help:

Read More >SUBSCRIBE VIA EMAIL

Recent Posts

POSTS BY TOPIC

- optical design (29)

- supply chain / inventory management (19)

- optics applications (14)

- standard optics (14)

- meet the team (13)

- custom optics (11)

- micro optics (11)

- optical assemblies (11)

- quality management (10)

- news (9)

- optical coating (6)

- medical optics (5)

- events (4)

- aspheres (3)

- cleaning optics (3)

- optical metrology (3)

- achromatic doublets & triplets (2)

- endoscope (2)

- mechanical engineering (2)

- Infrared (1)

- endoscopic test (1)

- large optics (1)